.jpg)

However, JIT is much more than the organized movement of materials and goods in, out, and through the company’s processes. This reduction is achieved by lowering inventory costs, improving efficiency, and reducing waste. Improving supplier relationships and reducing lead times can also lead to cost savings in the long run. By working backward, you verify that resources, personnel, and raw materials are available at the right time. Companies can quickly identify potential problems or delays and address these issues in advance. It also helps to ensure a continuous flow of manufacturing that runs smoothly and efficiently and that customer demand is met on time and at the right quality.

.jpg)

Innovations in Materials for Manufacturing

Some suppliers may increase the prices as well in response to the change in demand. Therefore, when the prices go up, a company’s profit margin can be greatly affected. In such situations, operations managers may feel that they should have bought stock well in advance. Two crucial factors or elements of the JIT are continuous improvement and the best utilization of inventory. Therefore, they refrain from engaging in mass production to avoid product degradation. Besides, firms use just-in-time methods to reduce activities that do not serve any value.

Common Misconceptions About Ant Control and What You Need to Know

- The Toyota Production System emphasized producing only what was needed when it was needed, which became a fundamental principle of the JIT inventory management system.

- Just-in-Time manufacturing relies highly on effective suppliers to reduce inventory.

- The right time is a time that will not impact the delivery date and agreed date to receive your products in the customer’s hands.

- They have a better understanding of seasonality and demand fluctuations which makes JIT implementation smoother.

- The main findings of this study are that non-online shoppers are unlikely to buy online because they prefer to shop traditionally and self-assess the quality of the goods before they buy.

- This reduces the ‘lead time’ for the company and the holding costs, simultaneously the losses of inventory are significantly minimized which varies based upon the nature of business.

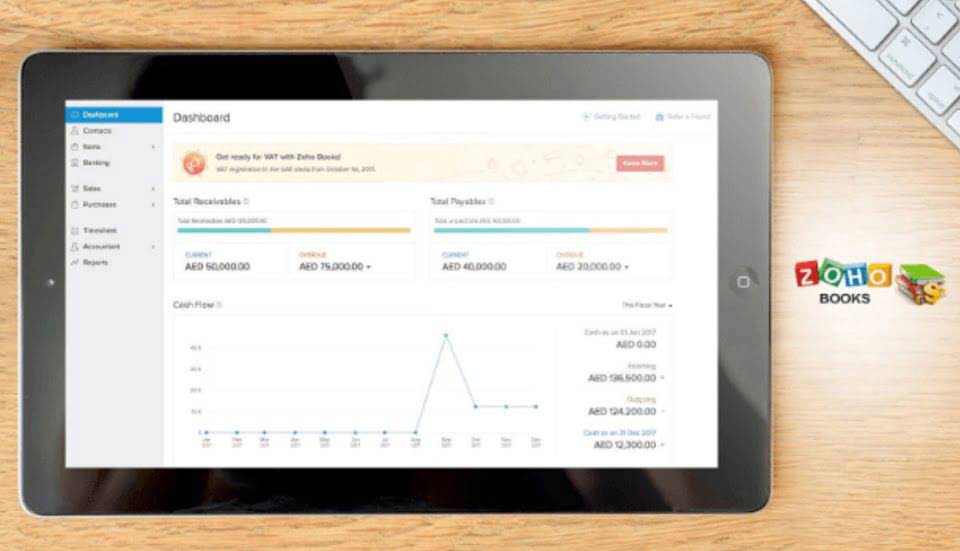

However, little empirical evidence about the relationships between e-shopping and in-store shopping is available. Nowadays, with the rapid development of Internet technology, online shopping is becoming common and even inevitable among Hong Kong people in different age. By providing a centralized data system and effortless and accurate communication between departments, an ERP system creates a basis for the implementation of JIT. As each data entry is reflected throughout the software, all departments instantly receive the necessary information for successfully executing the company’s JIT strategy. Overprocessing or performing unnecessary or excessive steps in the production process adds no value to the final product. JIT aims to eliminate non-value-added activities, streamline processes, and focus on value-adding steps.

Benefits of Kanban in JIT

- They must also have a good track record of timely delivery, consistent quality, and the ability to respond quickly to changes in demand.

- The Just in Time (JIT) model has its roots in the Toyota Production System (TPS), developed by Toyota in Japan in the 1970s.

- Kanban and JIT together bring overall production efficiency by having products available without excess inventory.

- Established businesses with good vendors and supply chain processes are best suited for JIT.

- Manufacturers can adopt many different production strategies, each with advantages and disadvantages.

Then, you create a production flow to minimise this waste and maximise efficiency. Toyota Motor Corporation utilized the same principle in the 1970s and called it the Toyota Production System. The short-cycle manufacturing system of Motorola and the continuous-flow manufacturing strategy of IBM are fundamentally similar to the just-in-time system.

Understanding Just-in-Time (JIT) Inventory Management

Standard work simplifies workflows, aligns to market demand, and supports continuous improvement, which is what JIT systems are all about. Advanced demand forecasting and flexible production schedules can manage demand fluctuation. Monitoring market trends and customer needs can help just in time manufacturing advantages and disadvantages businesses adjust JIT systems quickly and reduce stockouts and lost sales. Dell Technologies uses JIT in their supply chain to meet customer demand with minimal inventory.

Madis is an experienced content writer and translator with a deep interest in manufacturing and inventory management. Combining scientific literature with his easily digestible writing style, he shares his industry-findings by creating educational articles for manufacturing novices and experts alike. Collaborating with manufacturers to write process improvement case studies, Madis keeps himself up to date with all the latest developments and challenges that the industry faces in their everyday operations. Overproduction is manufacturing products in advance of or more than the demand specifies. It’s considered to be the most severe of the wastes by proponents of just-in-time manufacturing because it squanders time, space, and money, all the while masking the other problems within a company’s processes.

The results and findings show that consumers exhibited positive intention to make an online purchase in future and attitude is positively and strongly correlated with behavioral intention. The study also concluded the perceived benefits of online shopping, perceived merchant’s trustworthiness, consumers’ lifestyle and consumers’ prior ecommerce experience have direct influence on attitude. On the contrary, demographic profile, online shopping frequency and duration of daily internet usage found to have no impact on attitude. The research model applying Theory of Reasoned Action (TRA) can effectively be used to achieve the primary purpose of this study.

JIT logistics is a method of organising production whose objective is that supplies arrive at the factory at the exact moment (hence the name) when they are going to be used. In other words, the company receives the products it needs, in the exact quantity and at the right time to complete production. This strategy is also effective for automotive, electronics, and consumer goods production. These industries have a high demand for their products and need to respond quickly to changes in market trends. Strong suppliers are critical in ensuring that the production and delivery of goods remain on schedule.

Afonso é um profissional dedicado ao universo da corrida, com um foco especial na biomecânica e na nutrição esportiva. Como ex-atleta e formado em Fisioterapia, Afonso entende profundamente a importância de um bom par de tênis e uma dieta balanceada para um desempenho de corrida otimizado